Since January 2018, Javier Macía has managed the laboratory of synthetic biology for biomedical Applications at the Department of Experimental and Health Sciences, Pompeu Fabra University (DCEXS-UPF). Although the name of the lab only mentions biomedicine they also work in industrial and environmental products.

“We don’t do biology; we do engineering, but using biological elements as our working pieces”, explains the group leader. There is, however, a more fundamental part of the group’s research, which attempts to understand the principles behind the biological devices that they generate. Genetic circuits follow the same laws as electric ones; when you raise the expression of a gene, you lower that of another, because the cellular resources are limited. That’s why when they put the pieces together they don’t work in the same way as they do separately. That’s why it is so necessary to understand the systems and to make mathematical models and predictions before creating them.

Genetic circuits follow the same laws as electric ones; when you raise the expression of a gene, you lower that of another, because the cellular resources are limited.

Macía makes an analogy with engineering: “In synthetic biology, we are still in the stage of putting a truck on the bridge after having made the bridge, to see if it is strong enough; if not, we construct it again in a different way “. Understanding the principles behind what they design would help to make predictions and avoid the costs of this ‘trial and error’ way of working.

The group is small – five doctoral students, plus some external collaborators – but between their own projects and collaborations, they have five projects under way. “The members of the group have a very multidisciplinary interest; everyone is involved in all projects, and everyone does a bit of both the experimental and computational parts,” explains the leader of the laboratory.

Capsules against diabetis

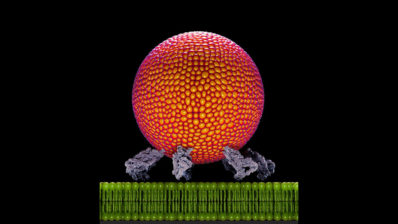

The group has funding from the Marató for a project done together with Francesc Posas, currently at the IRB, the Hospital Sant Joan de Deu and the University of Vitoriam to build cellular devices that control glucose levels. These are genetically manipulated human cells that have glucose sensors that, when touched, generate insulin and secret it. In Vitoria they have ‘encapsulated’ these cells (they have created nanocapsules where cells are trapped). These capsules are now being injected into mice. This system of capsules has the advantage that it is reversible, because they do not integrate anywherein the DNA, but are isolated, ‘floating’ in the tissue, so that they could be removed if necessary, explains Macía.

They have also developed an algorithm that finds the ideal intakes to control glycemic curves and have confirmed, in mice, that just by modulating food patterns the hyperglycemia curves can be reduced. “Combining the capsules and patterns of intake would be very interesting,” says the physicist. But modulation of the intake by itself is, in fact, already interesting, especially for people with type II pre-diabetes. This may prevent people from getting insulin injections if they control when and how they eat, following the indications of the algorithm. “The human physiology computational model that we are using is very good; in fact, it is approved by the FDA for its use in clinical trials“, confirms the scientist. “Our ultimate goal would be to have an app or something similar that suggests to diabetics what to eat and when, and that recalculates their diet if, for example, they could not avoid eating a croissant when they shouldn’t!”.

Our ultimate goal would be to have an app that suggests to diabetics what to eat and when to control blood glucose.

Intelligent cells

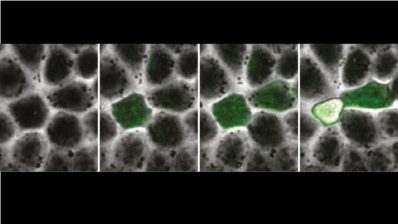

Another of the group’s projects – more exploratory and funded by the US Air Force and the US Navy – is to create cellular systems with the capacity for self-learning. For years, scientists have been able to design cells that detect the presence of certain markers and respond according to the combination of these markers. But the group is wondering whether the cells could be autoprogrammed, that is to say, modify their DNA themselves based on the signals they receive.

“What we have done has been to build cells that have all possible genetic circuits, but inactivated. The idea is that the cell, when a combination of specific signals is found, recognizes and modifies its DNA; with recombinases, cutting around and sticking here and there, so that you end up having the specific circuit of interest, among all the potentials you had initially. “This would be useful, for example, if the cells are in locations where we cannot go to program them, such as a space station,” says the group leader.

Paper sensors

A third project, related to the previous one and funded by a Spanish National Plan, attempts to make sensor cell circuits that detect a combination of complex signals. Peculiarly, these cells are being printed on paper, with “cellulose inks”. In a normal ink printer, the cartridges are filled with a cell culture medium plus a thickener. Each cartridge has a different cell type. When printing them, the cells are trapped in the paper, where they continue to grow and are able to release signals that travel through the paper and reach other cells.

When printing them, the cells are trapped in the paper, where they continue to grow and are able to release signals that travel through the paper and reach other cells.

The reason for doing this on paper is eminently practical; it’s cheap and easy to adapt to industrial use – 10,000 units per day can be printed – as well as highly reproducible because printers are very accurate. One of the potential uses, according to Macía, would be to identify, for example, the risk of preeclampsia. This does not depend on a single marker, but rather a complex combination of parameters. This set of cells (different cells living in different parts of the paper and communicating with each other) could be used as a reactive strip to detect different markers, analyse them and determine the risk of a pregnant woman to suffer from this disorder.

A spin-off to decontaminate

The most powerful project of the group right now, BIOM, was born with a clear aim of technological transfer. In fact, it plans to become a spin-off (with participation from UPF) this fall. “It all started when a private investor contacted us with a problem of manure,” smiles Macía. “Initially it was almost a hobby, but we saw that it had potential, and we took it to the university. We obtained funding from the ‘Seed product’ program of the AGAUR, and we are now looking for investors.” The project consists in adding value to livestock waste, specifically purines (liquid manure).

There are 8 million pigs in Catalonia. Together with China and Germany, it is one of the regions with the highest consumption of pigs. And a pig generates about 6 liters of purines per day. In fact, the local government (the Generalitat) has approved a moratorium of two years during which new pig farms cannot be opened, nor existing ones expanded, because the pollution problem is serious, with more than 47% of contaminated aquifers.

Biotechnology has long been used to modify microorganisms that help to decontaminate or eliminate residues. But if these systems do not generate money, they are not sustainable from an economic point of view. In fact, this has already happened several times, explains the researcher; good initiatives have died when the economic crises have come because they have ceased to receive funding. For this reason, the group has set itself the target of not only eliminating the problem (in this case the purines), but also to transform it into something useful – and with commercial value.

Biotechnology allows the modification of microorganisms that help to eliminate waste, but many of these systems are not economically sustainable. The Macía’s group has found how to convert this waste into something useful and valuable.

In particular, they are turning purines into bioplastics and wood adhesives. “The adhesives that are used to compact wood traditionally are made of urea and formaldehyde, but now it is known that the latter is carcinogenic when it goes into a gas phase. The European Union is making very restrictive regulations, but there is no real industrial alternative… We are creating one”. The researchers are using photosynthetic bacterial strains that absorb purine pollutants and produce a series of polysaccharides with the adhesion and resistance properties that are ideal for this use.

Apart from deciphering the technology, it is necessary to take into account the cost of bringing this into practice. “In an academic context, market costs are usually not taken into account, and it is essential to do so. In our case, for example, it would not be feasible to transport the purines to a purines processing factory if this is located more than 10km away from the livestock farms, because the cost of transportation would be greater than the benefit!”. But the scientists have found a solution: they have created a new type of photobioreactor, with a capacity of 40,000 liters, that allows to process the

in situ, in the own farms. Now they are studying how to license this technology, at the same time as building a pilot factory plant.

This system could also be used to treat human wastewater, and the group is already in contact with Aigües de Barcelona, the agency in charge of managing the water resources in Barcelona. “I like it because our projects are very diverse. And they are fun! “, concludes Macía.