Sira Mogas has not yet finished her doctoral thesis and is already listed as the first author of a publication in the journal Nature Communications thanks to the project that she has been working on: cellular devices printed on paper.

From the Laboratory of Synthetic Biology for Biomedical Applications of the Department of Experimental and Health Sciences, Pompeu Fabra University (DCEXS-UPF), the team led by Javier Macía has developed a technology to be able to print, in a simple and economical way, powerful devices that at first glance are nothing more than a strip of paper.

We have met with Sira and Javier to discuss this innovative and promising technology and to try to understand the complex simplicity surrounding the project.

What are cellular devices? What can they be used for?

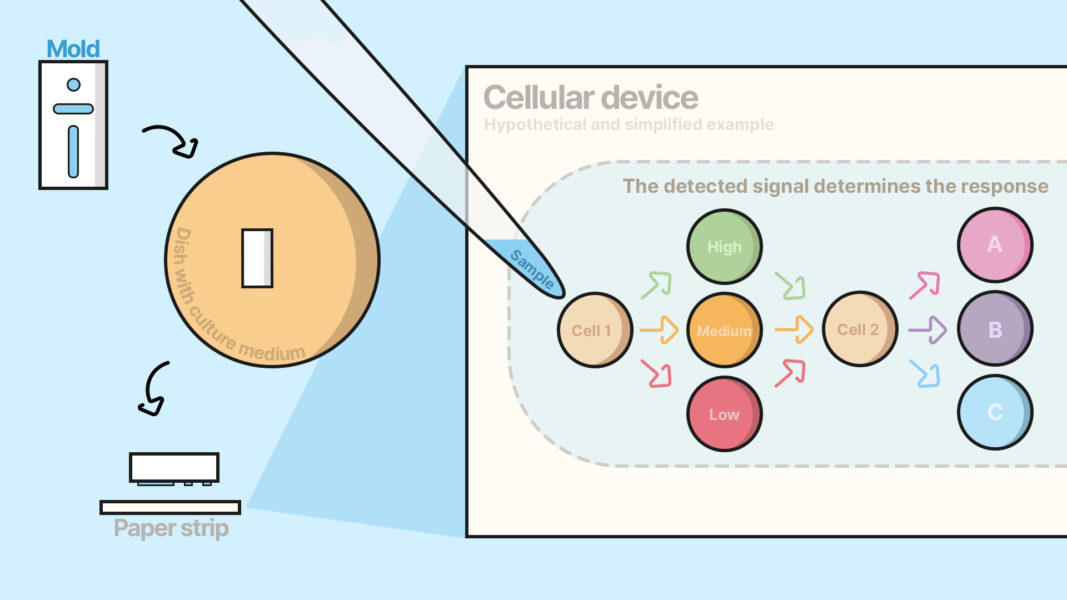

They are living devices, based on a combination of genetically modified cells, which can detect a multitude of signals, integrate them and generate a response based on pre-programmed rules. They have great potential for many applications, such as detection of diseases, the control of industrial processes or the analysis of pathogens or contaminants, and for years there have been many research groups working in this field.

Now we have developed a new technology that allows us to make these devices functional outside the laboratory, that is, they can be used without the need for any technology or an expert in molecular biology or synthetic biology to make them work.

“Our goal was to find a way to create complex cellular devices that could be used outside the laboratory in a simple way, for example, with a strip of paper”

Sira Mogas (DCEXS-UPF), first author of the study

We have found a way to print on paper our cellular devices (although it could be done on other surfaces, such as fabric), making them easily transportable outside the laboratory for future application.

What advantages do these ‘living’ sensors have over other electronic or biochemical sensors?

With electronic or biochemical devices, parameters such as pH or temperature can be analyzed, but the detection of cellular markers or microorganisms is much more complex. With living devices, we can decide the molecules of interest and take advantage of the cells’ own detection mechanisms to do so.

In addition, these devices have the advantage of being programable, that is, we are able to program a response based on the combination of the analyzed factors: so they not only detect the presence or absence of a marker, but different responses could be programmed based on the amount of detected signal, among others. Hypothetically, for example, a cellular device could be made on a bandage that, when placed on a wound, would change its color if the infection markers reached a specific threshold.

How is the design of these devices and the printing process that you have developed?

The design of the devices is linked to each application so first, in the laboratory, researchers have to generate the specific cells that detect the desired marker.

Once this is done, the order and combinatorics of the cells have to be configured, since this order determines the final answer we want to obtain. These devices have a circuit of cells that communicate with each other; they receive a biological signal, modulate it and emit a response. The type of modulation that each cell does (amplify the signal or cancel it, for example) and the point in the circuit at which it happens, will condition the signal received by the next cell and therefore the final result.

To understand it better, it is as if we had a pipe with three taps and three basins: the combination of open or closed taps will determine in which basin the water will fall and combining the taps in different ways we would obtain different results. These devices, based on the principles of computers and electronics, work in a similar way and we could get very complex answers.

The technology that we have developed allows us, once this device is designed, to print it on paper with “inks” that contain cells and to replicate it many times. The cells are placed in the mold, dipped in the medium, and stamped on top of a strip of paper, which becomes a cellular device.

Once the device is designed, the printing system could be automated (as if it were a T-shirt chain printing) and production scaled at an industrial level to generate a large number of cellular devices at low cost.

How applicable is this technology and what would be the next steps?

The range of applications is immense, since devices could be generated to detect multiple diseases or the presence of contaminants, for example.

In addition to being easy to use, produce and transport, we have found that these devices could be stored at -80°C almost indefinitely without affecting their usefulness, opening up an even greater range of possibilities.

“We wanted to make devices where the final user wasn’t necessarily a person with specialized scientific training and that the process was scalable at an industrial level to reduce prices”

Javier Macía (DCEXS-UPF), group leader

Right now we are in the second phase of the project, and we will look for practical applications, that is, applications that can reach the market to become products of interest. At the moment, in the laboratory we have made some mercury detector strips, and from here, we will look for other applications.

In the final part of my doctoral thesis, in which the project has been developed, we want to create a business structure, that is, creating a spin-off company of the project that is dedicated to applying the technology that we have developed to different market niches depending on the needs of the industry.

Mogas-Díez, S., Gonzalez-Flo, E. & Macía, J. 2D printed multicellular devices performing digital and analogue computation. Nat Commun 12, 1679 (2021).