Edgar Garriga is a third year PhD student in Cédric Notredame’s laboratory, at the Centre for Genomic Regulation (CRG). In March, like thousands of people across the country, he joined the coronamakers. This communityvoluntarily put their means and 3D printing knowledge to print the necessary materials to protect health care workers in their daily fight against the pandemic caused by the SARS-Cov-2 coronavirus.

The CRG has offered one of its 3D printers to this PhD student. From home, Edgar manufactures some ventilators parts, protective visors and other material. The UPF has done the same with its four 3D printers, which are now in the houses of some biomedical engineering students.

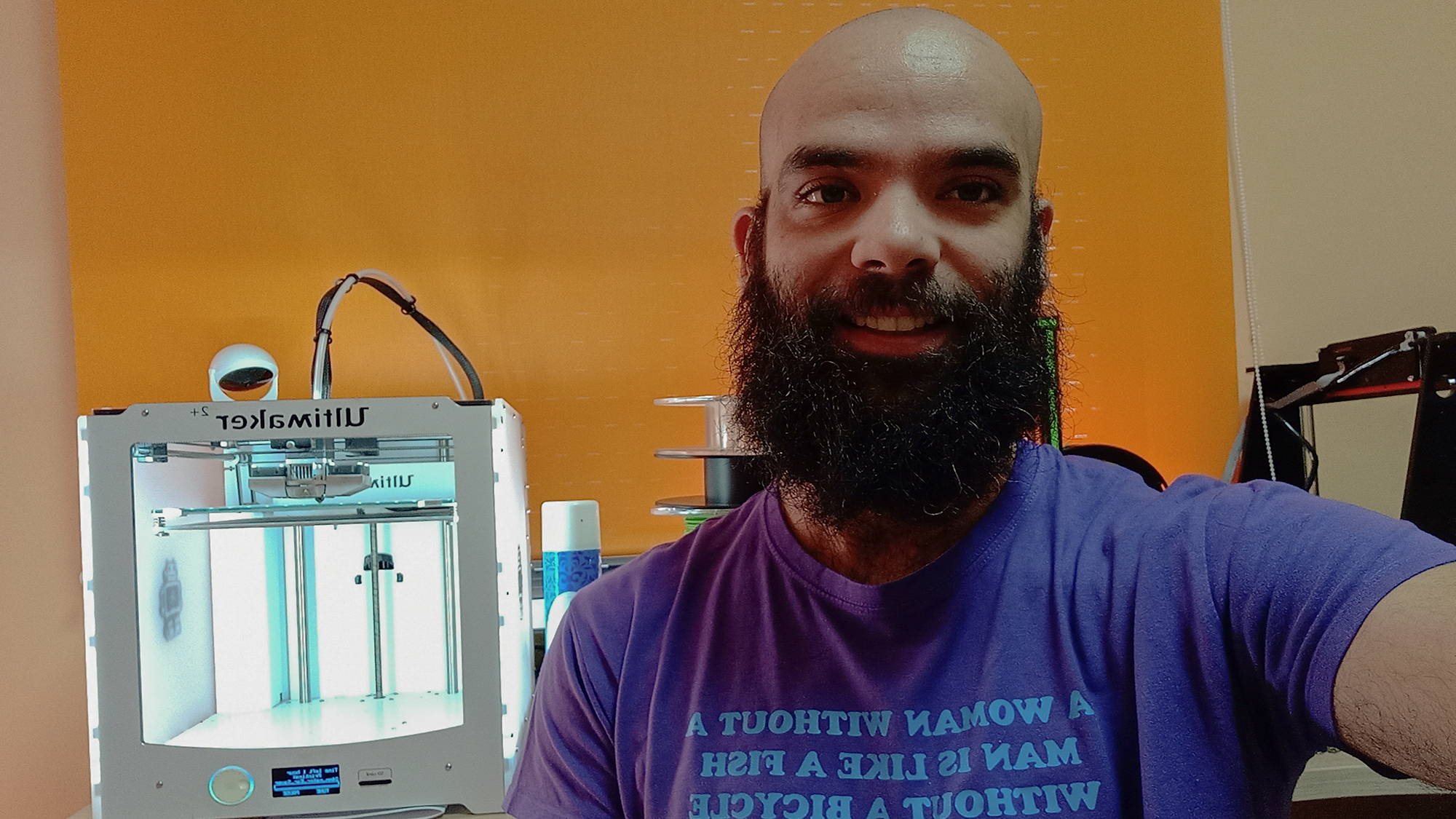

Edgar tells us about his experience as a coronamaker and how, with the help of the CRG printer and two others that he has at home, he is helping in this fight against COVID-19.

How did you end up being part of the coronamakers movement?

When I studied computer engineering, at the faculty we created a 3D printer: we bought it by parts and assembled it. I liked it and then I made one for myself, which I have been using to fix some broken pieces of my mobile phone or the fridge… Until I saw the news about makers in Italy

What news?

Valves for ventilators in hospitals were missing in Italy. They were very expensive (€11,000), but the problem was mainly the lack of stock. The Italian maker community came to the rescue and started creating them, about 500 a day – and for $1 each! When the news reached Spain, where we had not yet reached the italian extreme situation, we started contacting people from the health sector and asked them what they were going to need… They told us that ventilators were essential: “we will have to decide who lives and who dies due to the lack of ventilators”.

So you got down to work.

I spoke to my colleages, with whom I had created my first 3D printer. Some knew of people in Madrid who were starting to design ventilators… We got in touch and found the community of coronamakers.

And off to print ventilators!

Well, it wasn’t that easy. It took us almost a month to get the approval of the Health Ministry; the ventilators we designed had to pass clinical tests and still can only be used in an emergency – more for legal than technical reasons. But what excites me is that the designs are made, published and validated and can be useful elsewhere. For example, we are in contact with people in Argentina, Chile, Uruguay, Paraguay…

How does a 3D printer work and how do you make ventilators?

We don’t want to reinvent the wheel…. We take advantage of objects that already exist, especially for the medical part. For example, in the case of ventilators, the only thing we do with the 3D printer is a lever, the mechanism that tightens the ambu (a kind of bag that must be inflated to provide ventilation).

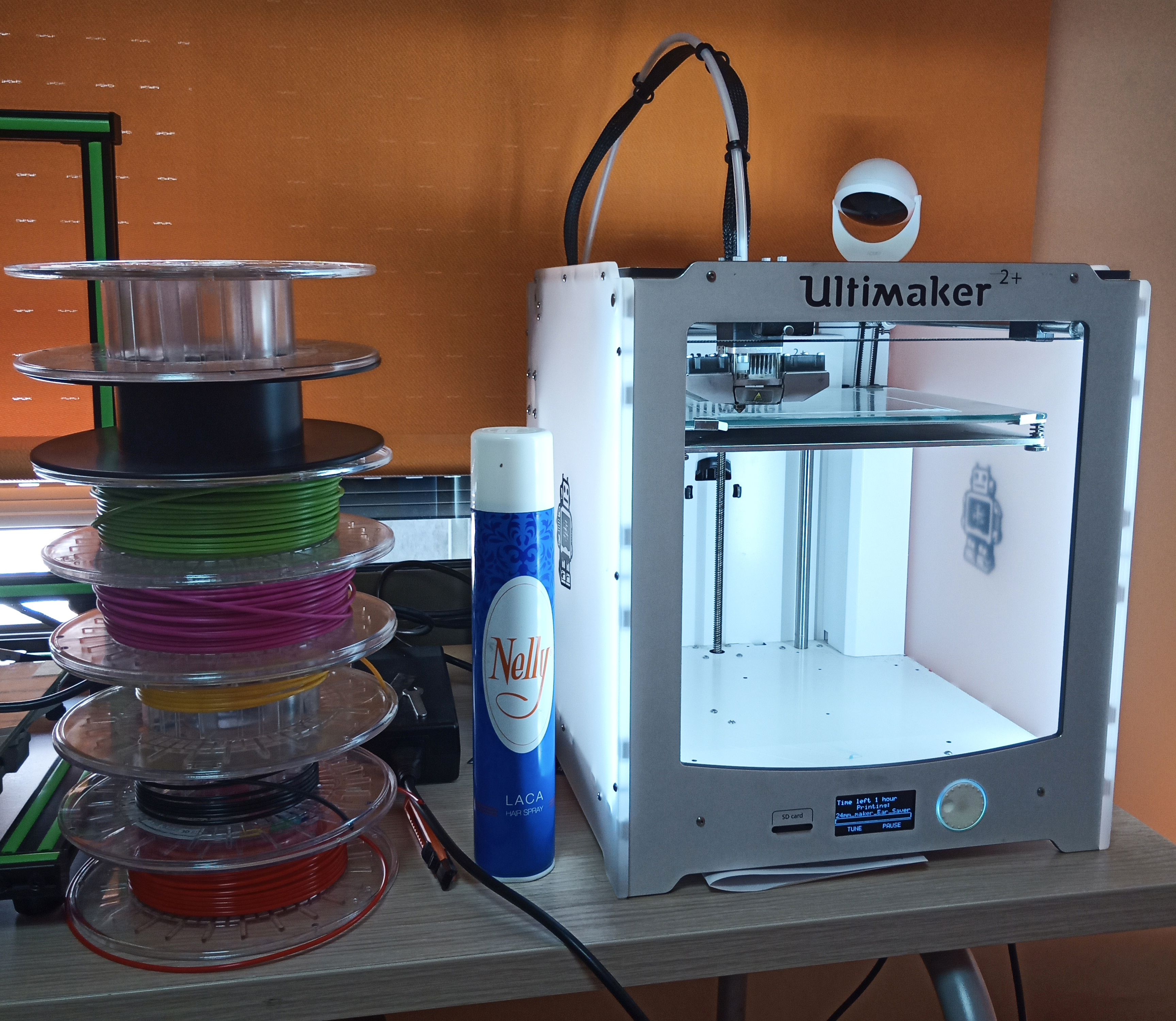

Actually, the 3D printer is very simple. We use plastic coils (PLA) of different diameters (mine is 2.85mm) as an input. The printer melts the plastic at 215ºC, and it exits through a 0.04mm hole – when exiting the melted plastic cools down and ‘regenerates’ in a much thinner plastic. This way you can print, as if it were ink, but putting layer upon layer, in three axes.

The 3D printer melts the plastic from the initial coils and uses it to print as if it was ink, but on three axes.

What other material have you generated besides ventilators?

We have made protective visors. As with ventilators, we make only the top piece that holds the plastic, a kind of headband. We now buy a transparent plastic, which is an acetate sheet but, at first, we used the covers of manuals or notebooks that we had at home!

Another thing we have done are ear savers – a small plastic band with different positions that are used to protect the ears of health care workers, since wearing surgical masks for so many hours, days, months, causes injuries.

They have also asked us for hands-free door openers, a kind of key ring to press buttons and open doors, avoiding physical contact with them.

In these three cases the designs have not had to be certified by the Health Ministry, because they are not considered official PPE (protectice personal equipment). If they are useful for those who use them, it is fine.

How much material have you created?

Since we started, we have generated more than 110,000 pieces (more than 70,000 visors and 40,000 ear savers). It takes about 1:30 hours to make a visor, if everything goes well. At the beginning it took longer, but we have been making the process more efficient, looking for how to use less plastic, less time… Now we are somewhat calmer, but the machines have been working 24 hours non stop for weeks – and my printers are in my room, so the noise did not help my insomnia!

And how many coronamakers are there?

In Spain we are more than 15,000, in Catalonia about 3,000. We all communicate by Telegram, we have groups at the state level, at the region level… We are all in contact, but we work locally; each group supplies its local hospitals.

But, in addition to the makers, there are many different people involved in this project; engineers, designers, health care workers… They tell us what they need and give us continuous feedback, which we greatly appreciate, because they virtually meet us after working 12 hours. Each one has a specific knowledge, and among all, a compendium of many people, in many different places, with different backgrounds, we make it possible. It is very enriching.

Throughout Spain there are more than 15,000 makers who have joined the cause to produce protective material against coronavirus for health care workers. They have created more than 110,000 pieces.

How do you organize yourselves?

We write down what we create in a shared Excel document. When you have, for example, 10 visors, someone from the organization comes to pick them up and give you new material. At the beginning, we used plastic that we had at home, but we spent a lot… Now companies that sell plastic are making donations to us, or selling it cheaper.

Sometimes we bring the material to the hospitals ourselves; in that case, we need a special permission from the hospital, since we should be at home by default. Some days I felt as if I was in a movie… For example, there is a neighbor of mine who is a nurse and works in a hospital where they wanted material and I couldn’t bring it to them. I didn’t know her before, but we came into contact and since we both have dogs, we would meet on the street when walking them and I would pass the package to her, without even talking – as if we were spies or drug dealers! In the end, with a lot of willpower, things turn out OK.

What does being part of this movement mean to you?

I am glad to be able to do my bit, although it has been difficult for me to accept that it is better to stay at home than to be outside, on the battlefield. I had driven ambulances before, and I volunteered if they needed to. But I was told that from home I am more useful, creating all this material.

Furthermore, I am also involved in research projects (NextFlow) where we hope that, when there is enough data on COVID-19, we can help analyze it. So while I would like to be with my friends out there at the front line, I understand that I am more productive here, at home. Once they sent me a photo of the entire emergency team at the Hospital Joan XXIII; they were all wearing the ear savers we made for them. I was very excited, because they work so hard for all of us, and I’m glad to know that we can help make their life somehow easier.

You can watch an extract of the interview (in Spanish) here: